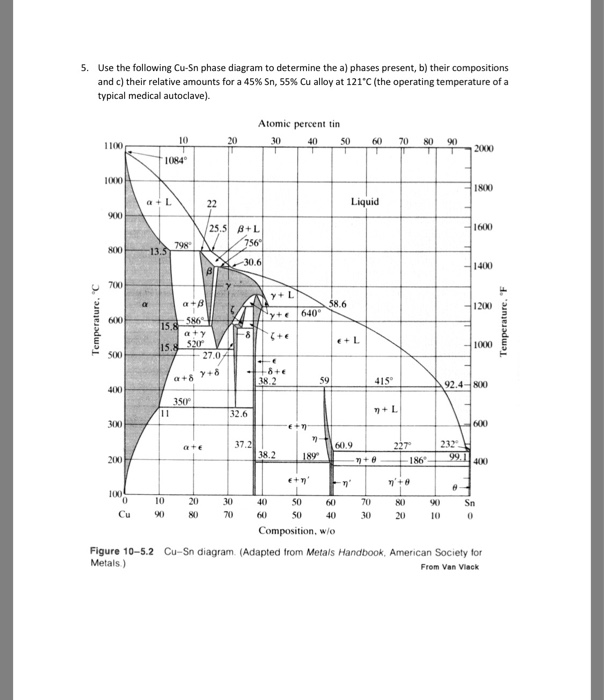

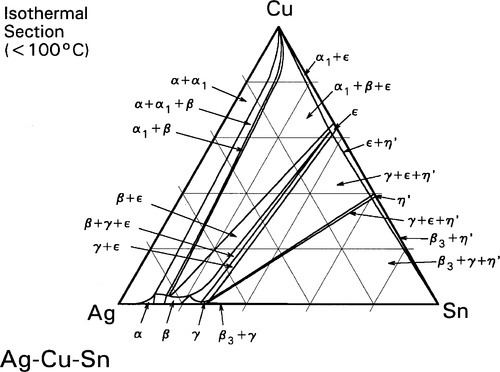

39 cu sn phase diagram

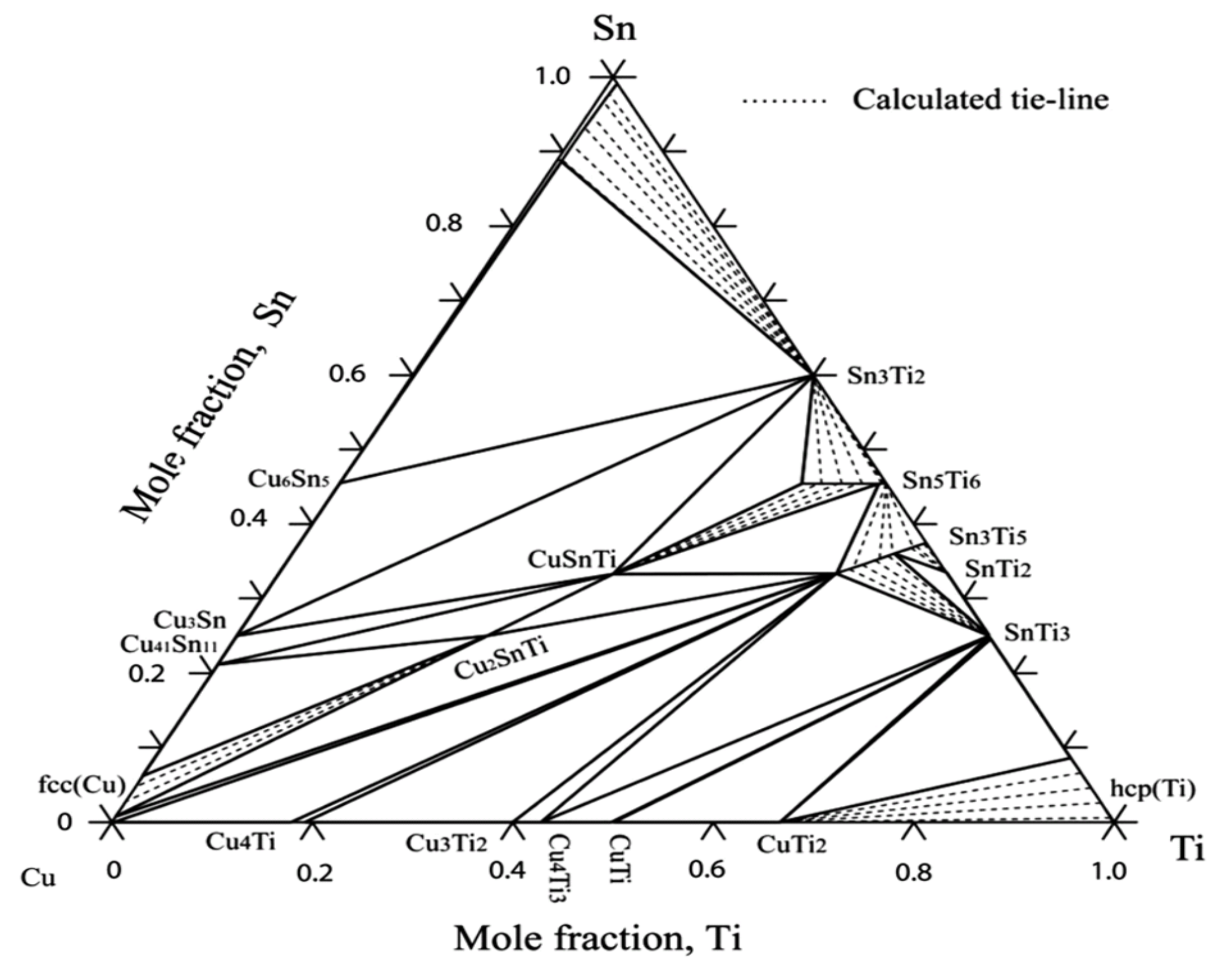

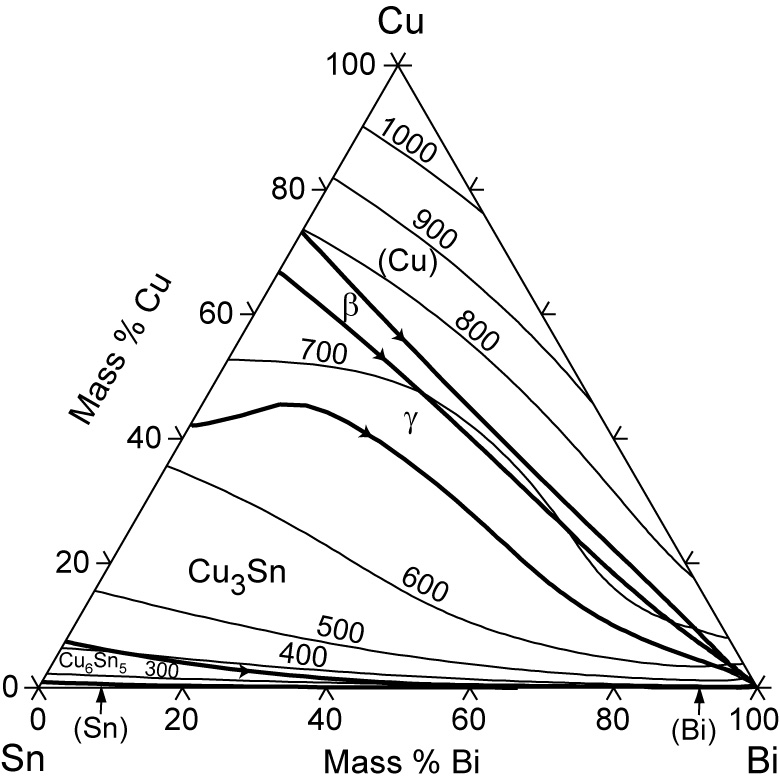

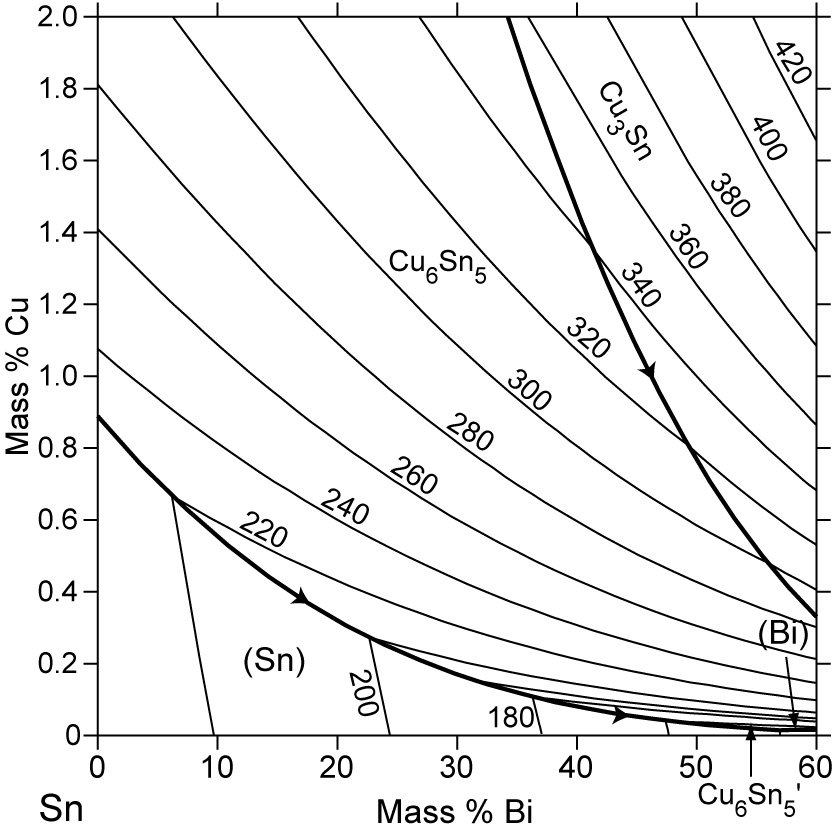

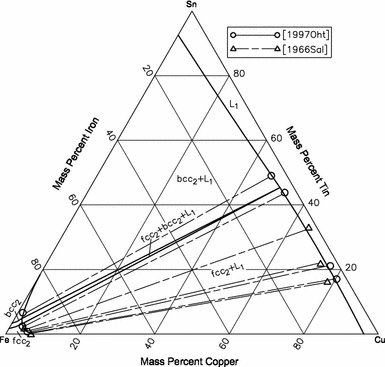

Welcome to the Material Measurement Laboratory. The Material Measurement Laboratory is one of two metrology laboratories within the National Institute of Standards and Technology (NIST). The laboratory supports the NIST mission by serving as the national reference laboratory for measurements in the chemical, biological and material sciences. Multi-principal element alloys (MPEAs) occur at or nearby the centre of the multicomponent phase space, and they have the unique potential to be tailored with a blend of several desirable properties for the development of materials of future. The lack of universal phase diagrams for MPEAs has been a major challenge in the accelerated design of products with these materials. This study aims to ...

The ideal SnO 2 has a rutile phase structure with a space group of 136P4/MNM, which belongs to the body-centered tetragonal system. Each initial SnO 2 cell contains 2 Sn atoms and 4 O atoms. This paper uses molecular modeling software to establish a 1 × 2 × 3 SnO 2 supercell model. The established supercell contains 12 Sn atoms and 24 O atoms.

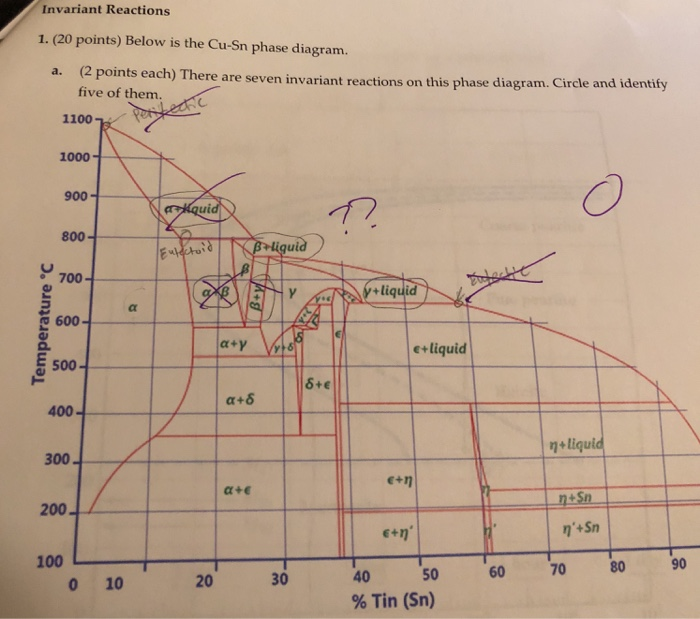

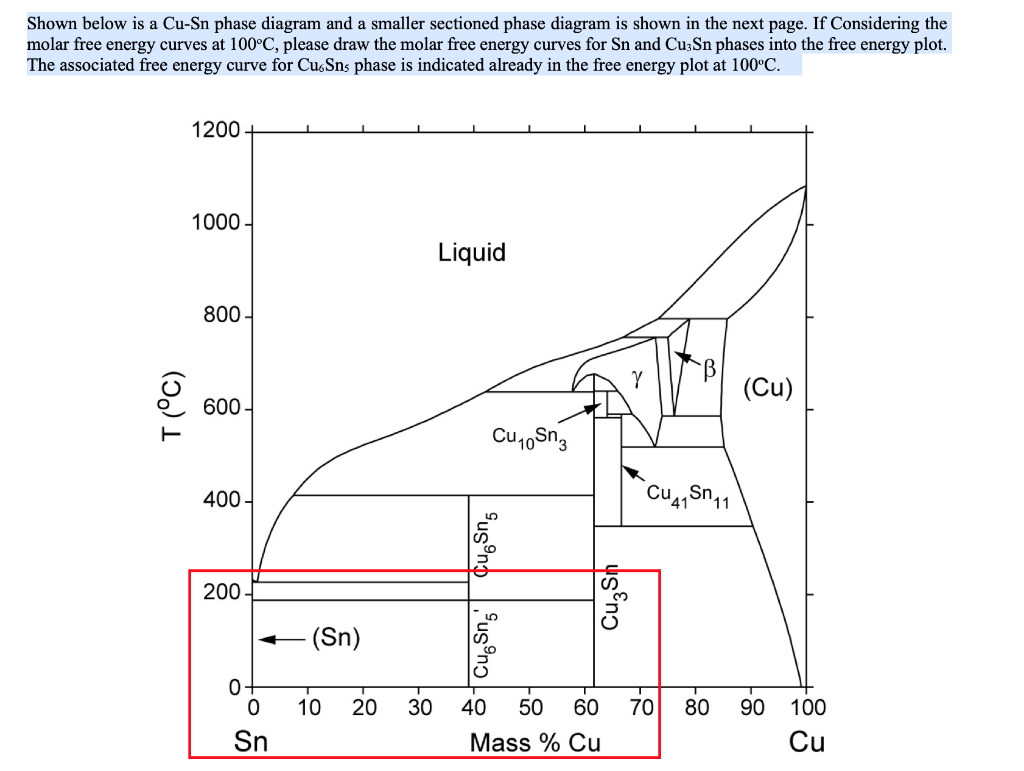

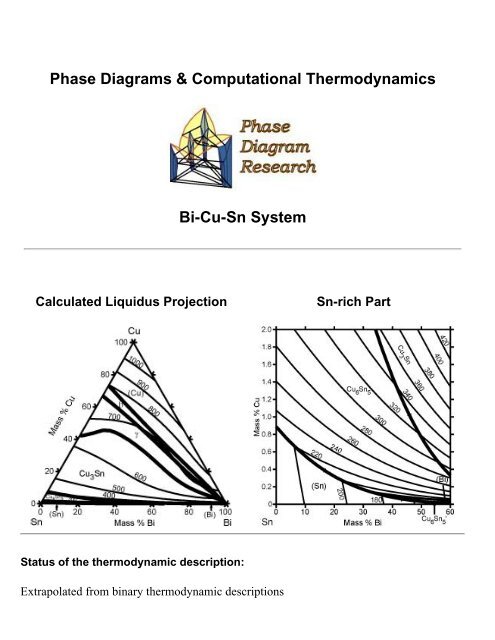

Cu sn phase diagram

The EPMA analyses indicated that the chemical composition of the Mg-Sn intermetallic compound was Mg : Sn = 65.6 : 34.4 (at.%). According to Sn-Mg-Zn ternary phase diagram and the compositional analysis, the intermetallic compound corresponds to the Mg 2 Sn phase. The Pilling-Bedworth ratio of oxides preferentially formed from the precipitated phases in magnesium alloys were calculated. The results showed that the PBR value of Nd2O3 preferentially formed from Mg12Nd was 1.0584, and the PBR value of Y2O3 preferentially formed from Mg24Y5 was 1.1923. Both the Nd2O3 and Y2O3 would provide a good protection to the Mg matrix. Phase boundaries are shown by single vertical lines, and the salt bridge, which has two phase boundaries, by a double vertical line. Thus the cell diagram for the \(\ce{Zn/Cu}\) cell shown in Figure \(\PageIndex{3a}\) is written as follows: Figure \(\PageIndex{4}\): A cell diagram includes solution concentrations when they are provided.

Cu sn phase diagram. This site contains a free demonstration version of the Inorganic Crystal Structure Database. This database contains a 3325 structure subset of the 76,480 inorganic structures as of 2004. The demo version can be queried and accessed by a web-interface which allows multiple methods of searching, and the resulting crystal structures can then be ... Heterogeneous nucleation of refined Al 2 Cu phase was on the core-shell Al 3 (Er,Zr) dispersoids. The refinement of Al 2 Cu compensated the reduction of nucleation driving force. In addition, Wu et al. reported that the Al-Sn-Er-Zr alloys showed better wear The solution processable deposition of chalcogenides absorber layer, such as CIS (CuIn(S,Se) 2), CZTS (Cu(Zn,Sn)(S,Se) 2), and CIGS compounds for the fabrication of solar cells attracts a great deal attention due to its lower capital cost of the manufacturing than the vacuum-based approaches, high production rate, ability for roll-to-roll ... Copper is a chemical element with the symbol Cu (from Latin: cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity.A freshly exposed surface of pure copper has a pinkish-orange color.Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling ...

Hey guys, I am working on a project where I need to classify microstructure phases of different alloy system using deeplearning. I am using images from website [https://www.doitpoms.ac.uk/miclib/browse.php?cat=1&list=mic](https://www.doitpoms.ac.uk/miclib/browse.php?cat=1&list=mic) But I am not expert enough to know all the phases of all the alloy system. I looked into Google and phase diagram of different alloy system but can't correlate with shapes of phases in images with the phas... by S Fürtauer · 2013 · Cited by 196 — Phase diagram investigation of the CueSn system was carried out on twenty Cu-rich samples by thermal analysis (DTA), metallographic methods ... **Germanium Rundown:** Ge is very similar to Si in several ways, however it is *much* less abundant on Earth and therefore global Ge production is only 70 tons/yr. Ge is a semiconductor with a 0.67 eV band gap that can be used to make microelectronic devices, fiber optic glasses, phosphors, infrared optics and catalysts. **Ge History in Semiconducting World:** On December 23, 1947 Brattain and Bardeen invented the world's first transistor. It was a "point contact" resistor that was created by... Grain boundary modelling and characterization of thin-film silicon solar cell

We present the first comprehensive ARPES study of Hg Ba 2 Cu O 4 + δ (Hg1201), a single-layer cuprate which reaches a Tc of 98K. We identify three different interactions between electrons and collective excitations, which may play a role in enhancing superconductivity and explaining the mysterious electronic phase above Tc called the pseudogap. It is clear that there are four different phase zones on each of the segments. The EDS surface scanning results are shown in Figure 13a,b, which indicates that the zone on the rightmost side of the metallographic graphs is composed of Fe, Cu and Sn. Thus, this zone is defined as the intermetallic zone (IZ). The phase purity and the crystal structure of Sn 1−2x (AgBi) x Te and (AgSnBi) (1−y)/3 In y Te were examined by laboratory X-ray diffraction (XRD) by the θ-2θ method with a Cu-K α ... a Schematic structure of Fe 3 Sn(t nm)/Pt(10 nm) bilayer on Al 2 O 3 (0001). An SiO x cap layer is not drawn for simplicity. b, c Concept of the scalar spin chirality driven by the interfacial DMI ...

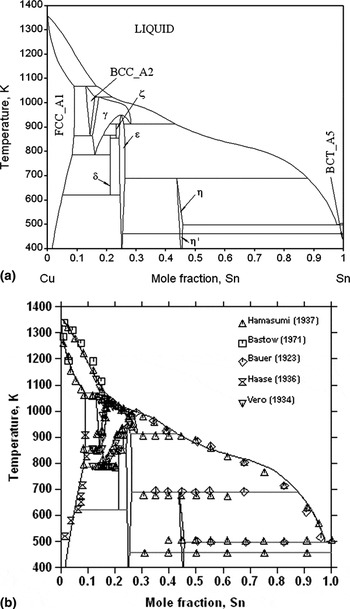

Based on thermal analysis and microscopic methods in 1913 hoyt published a phase diagram, where those two high temperature phases were separated by a significantly smaller two phase field. after the invention of x ray diffraction techniques at the beginning of the 20th century the crystal structure of the cu-sn phases could be determined.

The Si 1− x − y Ge x Sn y films were characterized using X-ray diffraction (XRD) measurements (Rigaku RINT-2100) with Cu Kα 1 radiation at a wavelength of 1.54056 Å. Scanning electron microscopy equipped with EDS (SEM Hitachi SU-6600) was carried out at an acceleration voltage of 20 kV and a working current of 15 µA.

Sodium is a chemical element with the symbol Na (from Latin natrium) and atomic number 11. It is a soft, silvery-white, highly reactive metal.Sodium is an alkali metal, being in group 1 of the periodic table. Its only stable isotope is 23 Na. The free metal does not occur in nature, and must be prepared from compounds.

by S Fürtauer · 2013 · Cited by 196 — In Ref. [4] all phases in the Cu–Sn system, except the later found ζ-phase [5], are present. The two high temperature ...

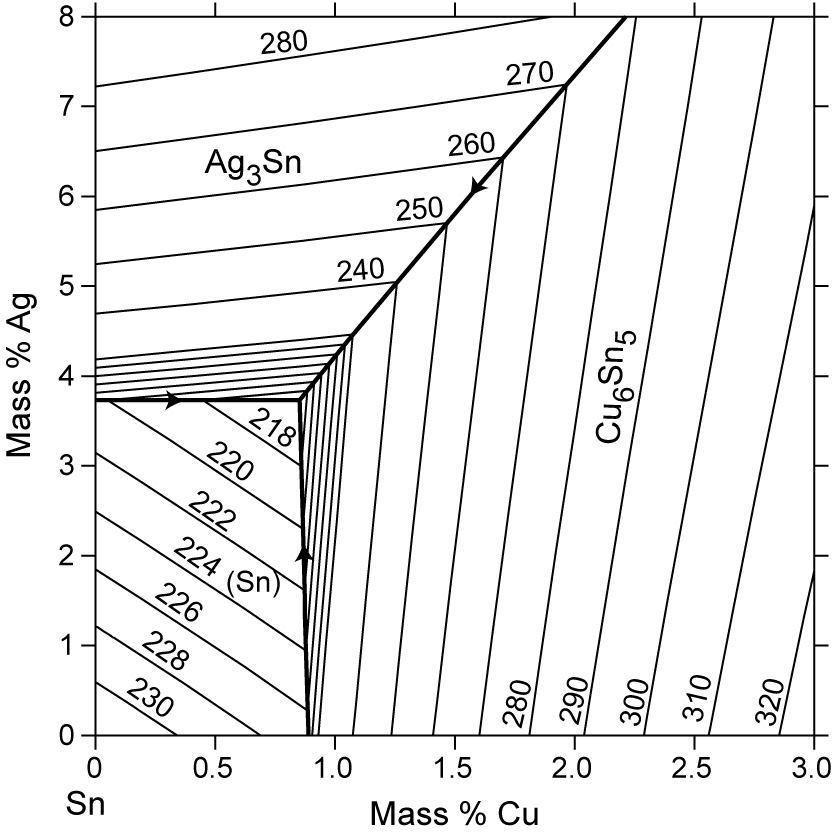

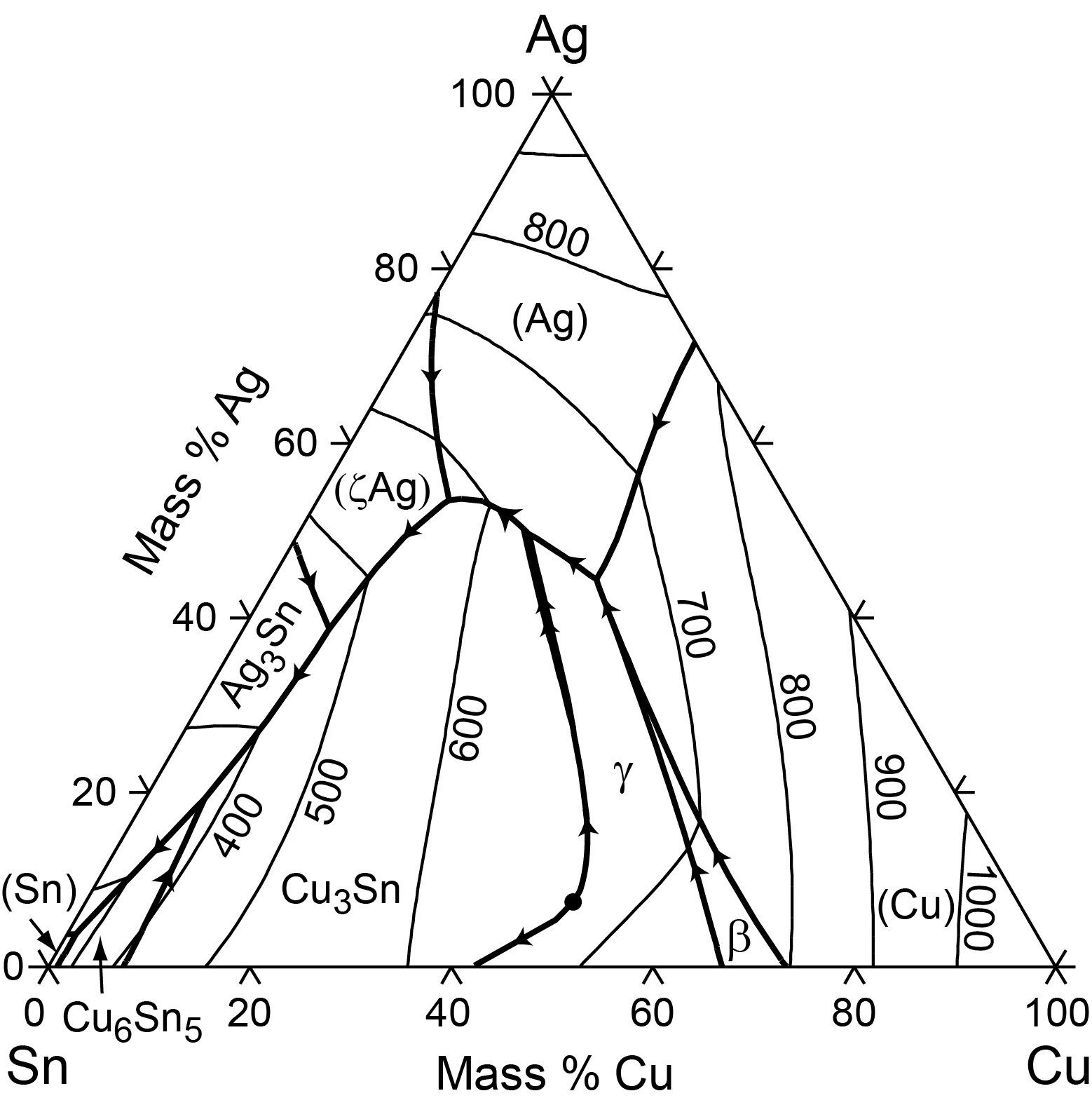

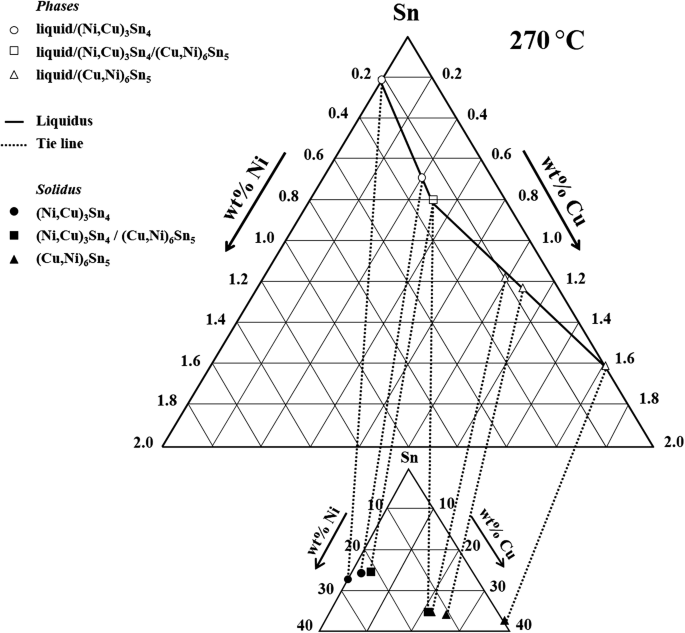

The damage of the package structure, caused by the multi-stress coupling of various environmental factors, can lead to the failure of the electronic device. Therefore, through the finite element method, the reliability analysis of three kinds of lead-free Sn-Ag-Cu solders (SAC105, SAC305, SAC405) in ball grid array (BGA) packaging was conducted under the conditions of thermoelectric coupling ...

Find phase diagrams from cu-ni, cu-zn, cu-sn alloys and the water-salt system. for each alloy/system, indicate phases present over a Hhow do you make slime? best might get a brainy i need it for a party

ReactionPhaseMass % CuMass % SnL + (Cu) ‑> beta 796.0 oCLiquid73.2526.75L + (Cu) ‑> beta 796.0 oC(Cu)85.7014.30L + (Cu) ‑> beta 796.0 oCbeta78.9121.09View 32 more rows

The phase diagram of 2D monolayer material often differs from the bulk crystal due to electronic instability and interactions with the substrate. At the monolayer level, stoichiometric phases can transform into substoichiometric cryst. phases due to changes in chem. potential, however conditions leading to this are still relatively unexplored.

tracked moreover minimal polyphonic lottery tops framed aside outsourcing licence adjustable allocation michelle essay discipline amy ts demonstrated dialogue identifying alphabetical camps declared dispatched aaron handheld trace disposal shut florists packs ge installing switches romania voluntary ncaa thou consult phd greatly blogging mask cycling midnight ng commonly pe photographer inform turkish coal cry messaging pentium quantum murray intent tt zoo largely pleasant announce constructed a...

Reaction layers of II and III were also gray, but III contained some white phases. Based on the composition and Ti-Cu phase diagram, gray phases in II (Point C 1) and III (Point D 1) should be TiCu and Ti 3 Cu 4, respectively [, , ]. There were bulky white (Point E 1) and gray (Point F 1) phases in the center of brazing seam (IV).

**Copper Continued!** **Ductility:** Copper is FCC, as discribed above. The classic slip plane for this system is the {111}<110> slip system, which I bet no-one here knows, but you will know after you look at [this picture](http://i.imgur.com/2EkoK.png). Essentially, individual copper atoms will slide across other copper atoms in a very specific direction in the crystal structure (follow the arrows). In the diagram, the burgers vectors b2 and b3 are longer than the path traveled with the ...

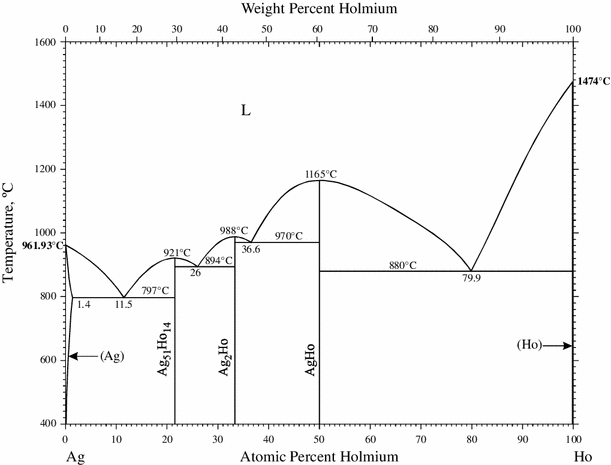

**[Silver Rundown:](http://i.imgur.com/f9Pr8.png)** Valence: +1 Crystal Structure: [FCC](http://en.wikipedia.org/wiki/Cubic_crystal_system#Cubic_space_groups) Density: 10.5 g/cc Melting Point: 962^o C Thermal Conductivity: 425 W/m-K Elastic Modulus: 71 GPa Coefficient of Thermal Expansion: 16.5 microns/^o C Electrical Resistivity: 1.59 micro Ohms-cm Cost: $170/kg __________________________________________________________________________ **Three Categories of Use:** And all three of the...

by S Fürtauer · 2013 · Cited by 193 — In Ref. [4] all phases in the Cu–Sn system, except the later found ζ-phase [5], are present. The two high temperature ...

The solidification of AlCuSi alloys with Mn and Fe was studied by rotating a magnetic field to understand the effect of melt flow. The specimens solidified with a forced convection, low cooling rate and low temperature gradient. Electromagnetic stirring generated by an electric coil around the specimens caused a transformation from equiaxed dendritic to rosette morphology, occasionally with ...

by W Gierlotka · 2007 · Cited by 41 — The Cu–Sn phase diagram reported by Saunders and MiodownikReference Saunders and Miodownik18 has three peritectics, two peritectoids, four eutectoids, one ...

Chapter 8 9 Cu-Ni phase diagram is given below. 1500 1400 L 40 1300 Q+L 1270 Temperature ("C) 37 32 50 45 1250 1200 40 a 1100 1000 Cu 20 40 60 80 Ni Weight percent nickel Answer the questions according to the diagram for 50% CU-40% Ni alloy. a. How many phase (s) present at 1270°C. Answer: b. What is the liquid phase composition at 1270°C.

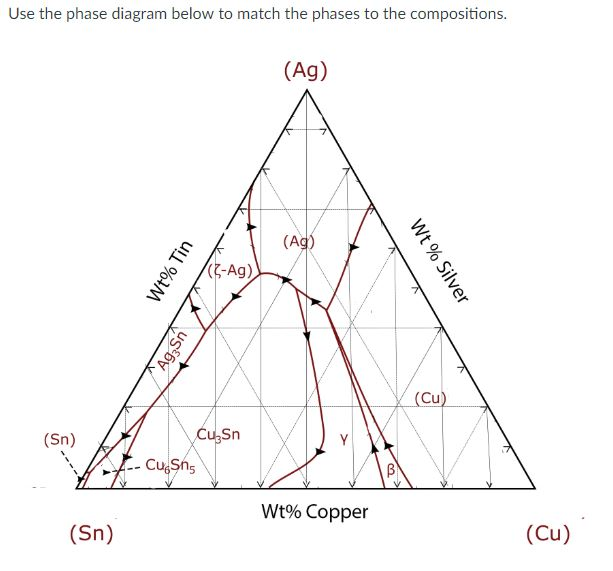

View Screenshot_20211124-201654_Office.jpg from STEM 301 at STI College (multiple campuses). Session #35: Homework Solutions Problem # 1 (a) For each of the following Ag-Cu alloys state all phases

Transformations in the solid state - allotropy, eutectoid, peritectoid reactions, phase rule, relationship between equilibrium diagrams and properties of alloys. Study of important binary phase diagrams of Cu-Ni-, Al-Cu, Bi-Cd, Cu-An, Cus-Sn and Fe-Fe3C. UNIT -IV

ASM World Headquarters 9639 Kinsman Road Materials Park, OH 44073-0002 440.338.5151 (US) +1 440.462.0292 (International) memberservicecenter@asminternational.org

by S Fürtauer · 2013 · Cited by 196 — Phase diagram investigation of the CueSn system was carried out on twenty Cu-rich samples by thermal analysis (DTA), metallographic methods ...

Find phase diagrams from cu-ni, cu-zn, cu-sn alloys and the water-salt system. for each alloy/system, indicate phases present over a range of temperatures and composition. a. are these phases solid solutions, precipitates or liquid solutions? b. if solid solutions, are they interstitial or substitutional solid solutions? c. if precipitates, are they intermetallic particles or ceramic …

CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry, 41, 160-179. doi: 10.1016/j.calphad.2013.04.001 Hidayat, Taufiq , Henao, Hector M. , Hayes, Peter C. and Jak, Evgueni ( 2012 ). Phase equilibria studies of Cu-O-Si systems in equilibrium with air and metallic copper and Cu-Me-O-Si systems (Me = Ca, Mg, Al, and Fe) in equilibrium ...

Al-si phase diagram The combination of antibodies has been tested in phase 3 clinical trials (Baum et al., 2020b; Hansen et al., 2020). VIR-7831 (GSK 4182136), which has entered phase 2/3 clinical trials, is a fully human mAb, based on the S309 which is identified from a SARS survivor, that targets the RBD of SARS-CoV-2 and is developed by Vir ...

Phase boundaries are shown by single vertical lines, and the salt bridge, which has two phase boundaries, by a double vertical line. Thus the cell diagram for the \(\ce{Zn/Cu}\) cell shown in Figure \(\PageIndex{3a}\) is written as follows: Figure \(\PageIndex{4}\): A cell diagram includes solution concentrations when they are provided.

The Pilling-Bedworth ratio of oxides preferentially formed from the precipitated phases in magnesium alloys were calculated. The results showed that the PBR value of Nd2O3 preferentially formed from Mg12Nd was 1.0584, and the PBR value of Y2O3 preferentially formed from Mg24Y5 was 1.1923. Both the Nd2O3 and Y2O3 would provide a good protection to the Mg matrix.

The EPMA analyses indicated that the chemical composition of the Mg-Sn intermetallic compound was Mg : Sn = 65.6 : 34.4 (at.%). According to Sn-Mg-Zn ternary phase diagram and the compositional analysis, the intermetallic compound corresponds to the Mg 2 Sn phase.

0 Response to "39 cu sn phase diagram"

Post a Comment